Manual Beam Welding - Requesting feedback on a design suggestion for replacing attachment plates

- Thread starter KaiFB

- Start date

- Tags attachment plates design welding

Looks good, though... my main fear about losing APs is making two plates floating in air stick together (like fins, for instance), if that makes any sense...

I like the solution!

I have a love/hate relationship with bolts. I like the freedom that you can take whatever and bolt it to the ship. That if you find something useful in space to salvage you can even transport it by, well bolting it to your ship. (edit.. but don't remove bolts!!!!!)

I have a love/hate relationship with bolts. I like the freedom that you can take whatever and bolt it to the ship. That if you find something useful in space to salvage you can even transport it by, well bolting it to your ship. (edit.. but don't remove bolts!!!!!)

I have three issues with the presented welding design.

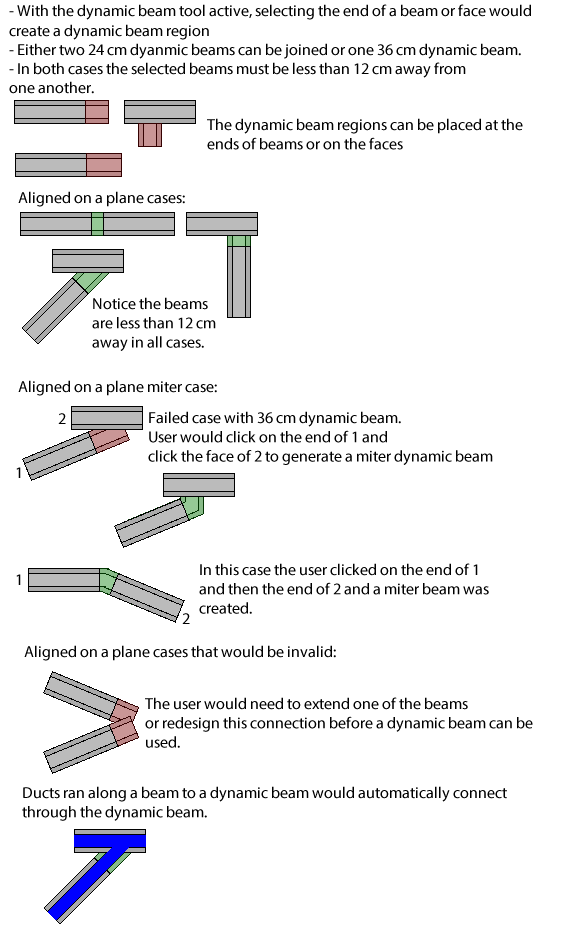

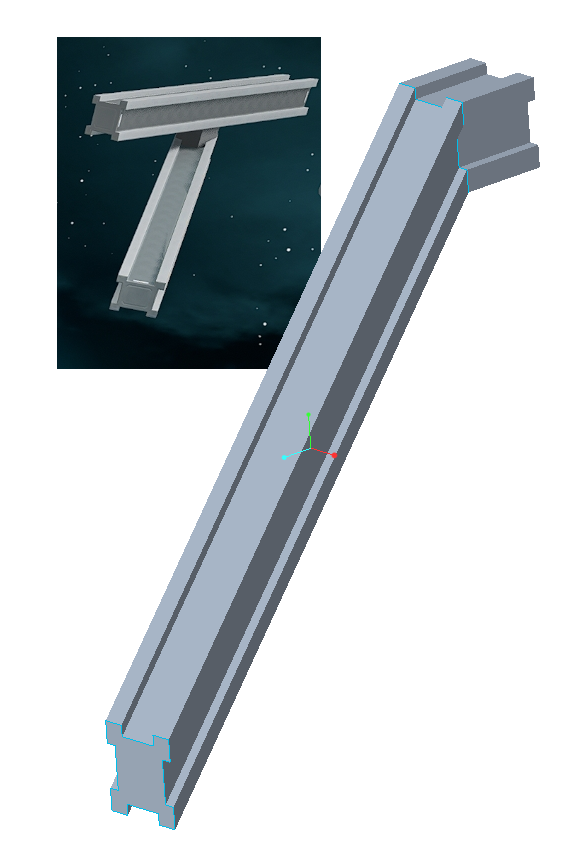

As seen in that image the dynamic beams work on any faces that share a plane. So in KaiFB's last image with the 4 examples the 3rd beam configuration would not be possible as the beams don't share at least one plane. That beam configuration is precisely the kind I'm referring to that cause awkward plating situations. In those cases I would argue what we need are new beams. For example, the beam shown below is extruded 192 cm then shifted 72 cm down and 72 cm to the right. This creates a beam that can work with other beams in a grid layout.

There's a lot of beam combinations if you go that route (343 beams), but there's also semi-intuitive plating parts for such slanted beams.

Using fake dynamic beams in theory would look really clean inside of ships with exposed beams. You'd see a continuous solid beam structure with no gaps.

I will say if welding blocks are the direction used, ensure they must connect two beams and maybe limit how many can be placed in an area. I could definitely see people just spamming these as filler pieces in their plating if there isn't a limit. (Kind of like how some designers use tons of bolts to cover up areas).

- Aesthetics. A ship is made of a solid frame. Some designers choose to leave beams exposed in places (like inside) and covered with plating in other areas. These welds essentially bring back the old idea of welding beams at a distance which leads to a lot of gaps. This makes ships (especially ones with exposed beams) look like a hodgepodge of various beams with no continuous structure. For players that want to include exposed beams at unconventional angles they have to either hide the welds or leave them visible - which doesn't look good. The welds themselves look like clipping geometry in the ship which is as bad as the current cables/pipes which clip other geometry. It makes ships look unpolished.

- The welds allow completely unconstrained beam structures with little regard to clean plating. Beams that aren't on a plane introduce a lot of angles that can't be plated cleanly. Ideally as new plating parts are introduced we'll be able to plate various frame designs nearly seamlessly (or with only 2 layers of plating). I don't foresee plate parts being added that could cover the cases introduced by arbitrary beam welding. (Worst-case this causes people to ask for clipping plates).

- Running ducts for power/piping along beams is amazing, but what do they do at welds? I strongly think that a frame in this game should be able to transmit ducts from any location on it to any other location. Magically jumping the welds from a gameplay point of view would be fine, but it's unintuitive.

As seen in that image the dynamic beams work on any faces that share a plane. So in KaiFB's last image with the 4 examples the 3rd beam configuration would not be possible as the beams don't share at least one plane. That beam configuration is precisely the kind I'm referring to that cause awkward plating situations. In those cases I would argue what we need are new beams. For example, the beam shown below is extruded 192 cm then shifted 72 cm down and 72 cm to the right. This creates a beam that can work with other beams in a grid layout.

There's a lot of beam combinations if you go that route (343 beams), but there's also semi-intuitive plating parts for such slanted beams.

Using fake dynamic beams in theory would look really clean inside of ships with exposed beams. You'd see a continuous solid beam structure with no gaps.

I will say if welding blocks are the direction used, ensure they must connect two beams and maybe limit how many can be placed in an area. I could definitely see people just spamming these as filler pieces in their plating if there isn't a limit. (Kind of like how some designers use tons of bolts to cover up areas).

Last edited:

- Joined

- Feb 23, 2021

- Messages

- 11

My only gripe is some designs, where you're working with angles in 2 axes or where you can't use the longest beams means your structural stability is reduced. AP's and bolts appear to be the only option for increasing this to a safe level. I've got a desgn to complete and trail which might make sense of this.

Overall though, great step forward. If we can get something similar for plates, I think we're close to getting golden.

Overall though, great step forward. If we can get something similar for plates, I think we're close to getting golden.